Lauric Acid - 99 - 100%

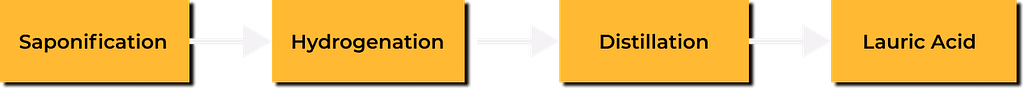

Manufacturing Process

The industrial manufacture of lauric acid is derived from saponification or the breakdown of fat (triglycerides).

Saponification method: the process utilizes high pressure and temperature to decompose refined palm kernel oil. The decomposition produces glycerine and branches of fatty acid. As various fatty acid branches are present, separation via distillation is required. Based on the fatty acid melting point, the mixture of fatty acids are distilled and the remaining heavy fatty acids such as lauric acid remains and collected. Additional production such as hydrogenation is required to remove unsaturated branches of the fatty acid.

Various grades of lauric are produced with other impurities of other fatty acids. The purity of lauric acid heavily depends on the distillation process. Therefore, higher grades of lauric acid demand higher energy consumption and sophisticated distillation design. The distillates of this grading are set to have 99% composition of lauric acid content.

Applications

1. Pharmaceutical Applications

Lauric acid is utilized for treating patients with viral infections such as the common cold, and swine flu. The compound has the ability to inhibit virus growth, prevents the binding to cell membrane, and the destruction of the cell membrane.

2. Food application

Lauric acid is a saturated fatty acid with a single branch 12 carbon atom chain. The compound’s melting point is sufficient to be used as a food shortening. Shortening is mainly used in baking to develop the tender and flaky texture of the food.

3. Cosmetic application

Lauric acid is used as a raw material to manufacture soap and shampoo. The transesterification process between lauric acid and sodium hydroxide to create crude soap.